Shopping Cart

Your shopping cart is empty!

Welcome visitors! You can login or create an account.

| Enhanced AAS II Contour Cutting System (Puma IV LX model only) |

|

The Puma IV series features a standard Automatic-Aligning System(AAS

II) to guarantee precise contour cutting by detecting the registration

marks on digitally produced images. Functions include: |

| Tracking Ability |  |

| The exclusive grid drum is precisely engineered to provide superb tracking ability. |

| Versatility |

| Puma IV is a versatile machine with the ability to plot and cut without having to alter the plotter's mechanical configuration. For vector cutting, simply install a blade holder; for plotting, simply install the drawing pen or a ballpoint pen. |

| Accurate and smooth operation |  |

| Puma IV incorporates a precision electro-mechanical design, which ensures an extremely accurate cutting capability. The state-of-the-art, closed-loop, high-speed digital servo drive system provides smooth, quiet, and fast operation. |

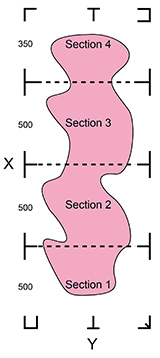

| Section Cutting |

Section cutting divides the long plot data into sectional output jobs

to gain higher cutting quality and increase precision. GCC Puma IV

series scan registration mark of section 1 and cut the plot data in

section 1, and then it scan registration mark of section 2 and cut the

plot data in section 2, and so on. |

| Segmental Positioning (Puma IV LX model only) |

Puma IV series features Segmental Positioning function which can

correct the crooked print. Printed image may be crooked because the

printing shifts, and Segmental Positioning function can scan the

registration marks one by one automatically to calibrate shift. |

| Auto Rotation (Puma IV LX model only) |

New registration marks defined to detect material feeding direction.

Puma IV detects the unique registration marks to distinguish material

feeding direction and rotate cutting content automatically. You don’t

need to rotate the material by yourself. |

| Triple Port Connectivity |

| Puma IV series supports triple port connectivity with USB, serial and Ethernet ports. The USB port provides faster and convenient data transmission between the computer and Puma IV. Ethernet connection enables multiple Puma IV to be operated by one PC and multiple PCs to share a single unit. Triple port connectivity provides users a great flexibility for data transmission. |

| Handy grooved cut-off tool |  |

| This handy and innovative design allows you to cut off a finished job in a straight line easily reducing the possibility of wasting usable material. |

| Windows Drivers |

| Puma IV includes a Windows driver that allows sign makers to edit signs from CorelDraw and output directly to Puma IV. It is very simple and easy to make signs with Puma IV. |

Friendly operation |  |

| The user-friendly control panel comes with a large 20-digit x 2-line LCD and 14 control buttons, providing easy operation and simple navigation. The LCD allows users to monitor all operational settings including offset value, quality mode, cutting speed and cutting force. Buttons on the Puma IV include frequently used functions such as speed, force, offset and cut test. 4 sets of prestored job settings for frequently used material can be stored in Puma IV. These settings include cutting speed, blade offset, cutting force, as well as movement speed during tool-up and cutting. |